Low temperature condensation recovery of VOCS exhaust gas

VOCs exhaust gas is a kind of waste gas that causes serious harm to the environment and human beings. Air pollution is one of the most prominent environmental problems in China, and industrial exhaust gas is the main source of air pollutants.

Keyword:

LED

Category:

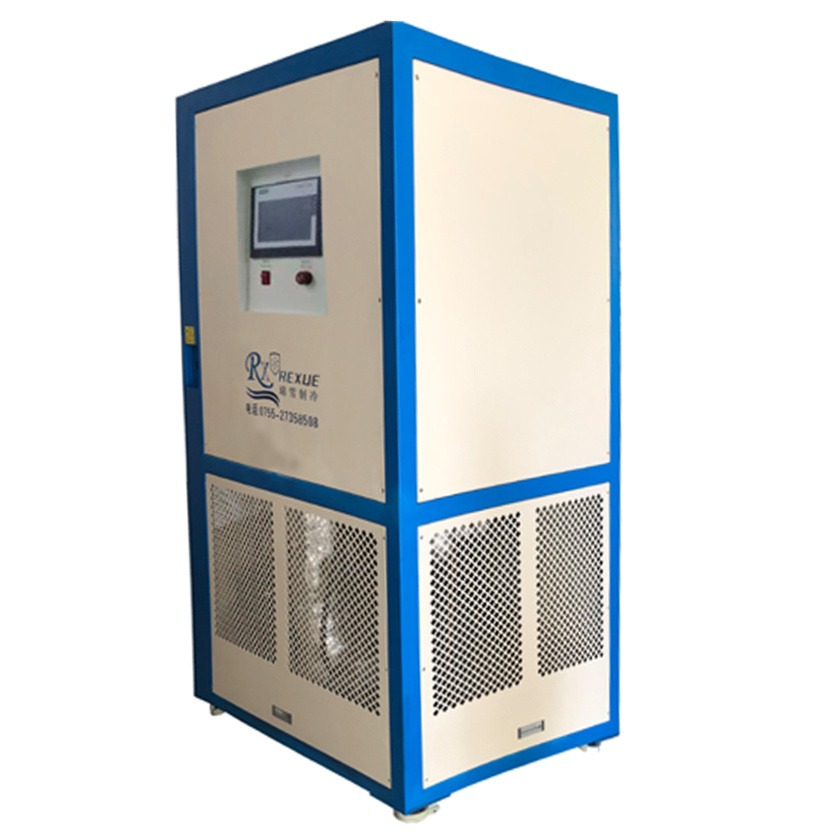

Vocs Exhaust Gas Condensation Device

Low temperature condensation recovery of VOCS exhaust gas

- DESCRIPTION

- Main features

- Model

- Application

-

VOCs exhaust gas is a kind of waste gas that causes serious harm to the environment and human beings. Air pollution is one of the most prominent environmental problems in China, and industrial exhaust gas is the main source of air pollutants.

Actively respond to the call of the environmental protection department to produce benzene, toluene, hydrogen chloride, sulfuric acid mist and other waste gas pollutants generated in the production process, and the existing waste gas treatment facilities of the project can only meet some of the requirements of organized waste gas treatment, and the collection and disposal of fugitive waste gas cannot be completely covered. In order to further do a good job in project environmental protection, conscientiously implement the national policy and normality on environmental protection, protect the physical and mental health of production staff and the quality of the surrounding environment, and minimize the impact on the surrounding environment.

Industrial waste gas, oil and gas recovery, VOCs gas condensation recovery device is generally used for hydrocarbons, aromatics, alcohols, ethers, ketones, esters and other gases, it is the VOSC gas condensation, (cold box heat conduction medium heat exchanger) inside the heat transferred to the refrigerant after cooling, the use of the difference in saturated vapor pressure at different temperatures of the substance, through cooling to make the oil and gas to reach the supersaturated state condensed into liquid direct recovery, a very small part of the gas into the post-stage unit for reprocessing. For the recovery of solvent gas, it can meet the environmental protection emission standards of tail gas according to demand; If the gas has a low boiling point gas, the adsorption treatment and other processes are separated and recycled again to make the emission gas meet the environmental protection requirements.

Condensation recovery method and principle:

The condensation method is to introduce the waste gas of industrial production directly into the condenser, through the role and reaction of adsorption, absorption, analysis, separation and other links, recover valuable organic matter, recover the waste heat of the waste gas, purify the waste gas, and make the waste gas meet the emission standard. When the organic waste gas concentration is high, the temperature is low and the air volume is small, it can be purified by condensation method, which is generally used in pharmaceutical and petrochemical enterprises. Usually one or more stages of other organic waste gas purification devices are installed after the condensate recovery device to achieve standard discharge. The volatile VOCs gas is introduced into the equipment cold box (the device sets the condensation temperature 5°C-45°C-80°C-120°C), other temperature zones can be customized for step-by-step condensation and liquefaction recovery according to needs.

Condensation principle: the high temperature and high pressure refrigerant gas discharged by the compressor when the compressor refrigeration system works enters the condenser and is condensed into a high-pressure supercooled liquid, and the vapor-liquid two-phase mixture enters the evaporator {primary heat exchanger, secondary heat exchanger, tertiary heat exchanger) when the compressor refrigeration system is working, and the refrigerant absorbs the heat of the heat conduction medium through the evaporator for self-gasification, and the refrigerant is fully vaporized and then sucked into the compression chamber by the compressor into the next cycle.

The low-temperature refrigerant medium is transported to the VOCs gas condensing cold box by the circulation pump for heat exchange with VOCs gas. The whole machine system continuously circulates through the above process, so as to achieve the purpose of continuous cooling and liquefaction recovery of VOCs gas. VOCs gas condensation - the gas is cooled down after transferring heat to the refrigeration wattle in the condensing unit heat exchanger {ie: cold box heat conduction medium heat exchanger), and the difference in saturated vapor pressure of substances at different temperatures is used to condense oil and gas into a supersaturated state by cooling and condense into a liquid state for direct recovery, and a very small part of the gas enters the post-stage unit for reprocessing.

Industrial waste gas, oil and gas recovery, VOCS gas condensation recovery device use: for industrial waste gas, oil and gas recovery, VOCs gas single material or multi-material condensation recovery.

1. Hydrocarbons · Such as gasoline, crude oil, fuel oil, kerosene, diesel, heavy oil, mixed hydrocarbons, etc

2. Aromatics: benzene, toluene, xylene, styrene, naphtha, etc

3. Alcohols, ethers, ketones, esters, etc.;

Industrial waste gas, oil and gas recovery, VOCS gas condensation recovery device use place:

First, common organic waste gas classification

VOCs (Volatile organic compounds), that is, volatile organic compounds, are a common class of air pollutants, produced in paint production, chemical fiber industry, metal coating, chemical coating, shoe leather, plywood manufacturing, tire manufacturing and other industries. Harmful volatile organic compounds mainly include acetone, toluene, phenol, dimethylaniline, formaldehyde, n-hexane, ethyl acetate, ethanol, etc.

Volatile organic waste gases (VOCs) in industrial enterprises are divided according to the source of production, mainly as follows:

1. Painting exhaust gas: the main components are acetone, butanol, xylene, toluene, ethyl acetate, butyl acetate and other volatile organic compounds, mainly produced in paint spraying and other surface treatment enterprises, common treatment methods are oil curtain absorption, water curtain absorption, and then with two and three stages of activated carbon adsorption.

2. Plastic, plastic waste gas: the main component is plastic, plastic and other particles volatilized polymer monomer during heating processing, because the composition of plastics and plastics is more complex, the exhaust gas mainly contains ethylene, propylene, styrene, propylene and butadiene and other olefin plastic polymer monomer, but the concentration is generally low and the air volume is large. The enterprises involved mainly include plastic granulation enterprises, chemical fiber production enterprises, injection molding enterprises, rubber production enterprises, etc., and the treatment methods mainly include activated carbon absorption, plasma purification, etc.

3. Stereotyped exhaust gas: the main components are aldehydes, ketones, hydrocarbons, fatty acids, alcohols, esters, lactones, heterocyclic compounds, aromatic compounds. The enterprises involved are mainly dyeing and finishing enterprises and chemical fiber production enterprises, which usually use water spray treatment process and electrostatic adsorption treatment process.

4. Chemical organic waste gas: mainly produced by chemical enterprises, the waste gas composition has a greater relationship with the types of chemical products designed and produced by chemical enterprises, and purification collection and treatment methods such as condensation recovery and catalytic combustion technology are generally used.

5. Printing exhaust gas: the main components are toluene, non-methane total hydrocarbons, ethyl acetate, ethanol, etc. volatilized in the ink. The enterprises involved are mainly enterprises containing ink printing processes, mainly such as packaging products, printing and other companies, generally using activated carbon adsorption.

6. VOCs organic waste gas mainly comes from the waste gas emitted in the production process of the chemical industry, printing and other petroleum and chemical related industries. Volatile organic compounds in organic waste gas are called VOCs (Vlatile organic compounds), in many industries such as painting, printing, shoe making and chemical production, some industrial products production processes will have a large number of volatile organic compounds (VOCs) exhaust gas emissions.

7, VOCs main components benzene, acetone, ethyl acetate, phenol, dimethyl sulfur, thiophene, methyl mercaptan, carbon disulfide, amide, etc.

At the same time, our company can design and produce low-temperature type, anti-corrosion type, explosion-proof industrial waste gas, oil and gas recovery, VOCS gas condensation recovery device according to user requirements. It can provide users with engineering design, equipment production, engineering installation, maintenance and other projects. Provide one-year free maintenance, lifetime maintenance. Perfect after-sales service, win the favor of our customers. Welcome to inquire!

-

Please enter the content...

Packaging and shipping

Analyze products

formulate a scheme

Plan rectification

Safety debugging

Equipment manufacturing

Customer determines the plan

Understand customer needs

previous page

next page

previous page

No.

next page

Online message

Related products