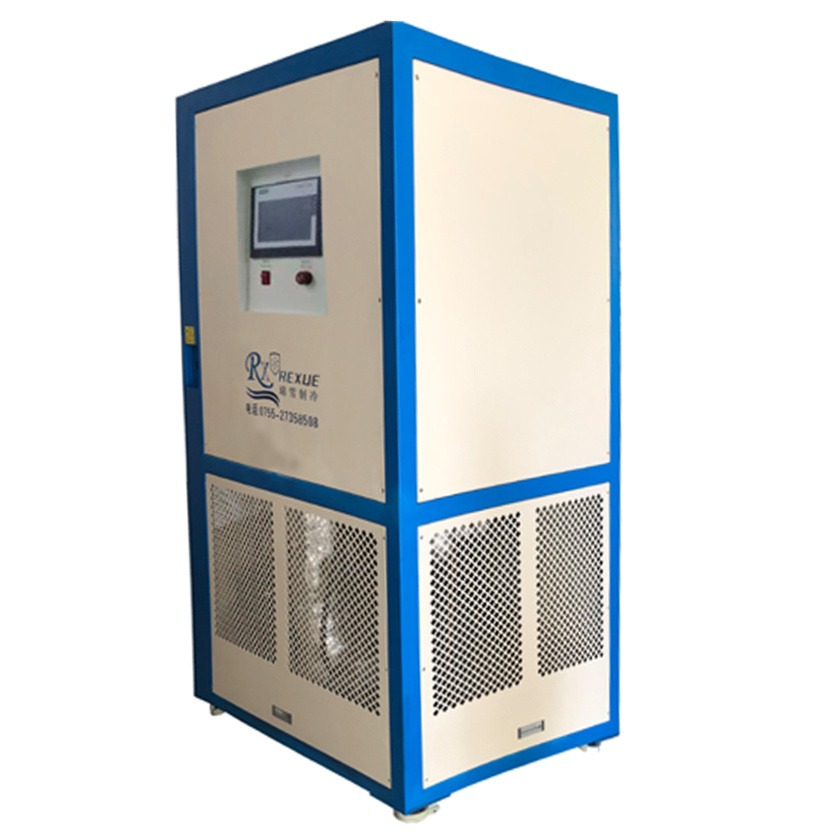

Concrete cooling chiller

The concrete chiller can make the concrete temperature drop below 15 degrees. At the same time, cement, stone, yellow sand in the temperature between 20-30 degrees out of the product quality is good, and the summer ambient temperature is very high, the water temperature is also high and not conducive to mixing, so the use of special concrete batching plant to cool the industrial chiller directly provides 0-10 °C chilled water, or 0-2 °C ice water mixture, can fully meet the national quality inspection concrete cooling requirements for process cooling source.

Keyword:

LED

Category:

Concrete Cooling Unit

Concrete cooling chiller

- DESCRIPTION

- Main features

- Model

- Application

-

Concrete cooling chiller

The concrete chiller can make the concrete temperature drop below 15 degrees. At the same time, cement, stone, yellow sand in the temperature between 20-30 degrees out of the product quality is good, and the summer ambient temperature is very high, the water temperature is also high and not conducive to mixing, so the use of special concrete batching plant to cool the industrial chiller directly provides 0-10 °C chilled water, or 0-2 °C ice water mixture, can fully meet the national quality inspection concrete cooling requirements for process cooling source.

1. Concrete cooling chiller adopts the most advanced international ice storage technology, which has the functions of refrigeration, ice making, cold water supply and ice delivery, can directly provide 0-2 °C chilled water, or 0-5 °C ice water mixture, can fully meet the demand for concrete cooling process cooling source, the refrigeration unit can set the water temperature according to customer requirements, the temperature control range 0 °C ~ 10 °C, effectively reduce the heat generated when mixing concrete.

2. Concrete cooling chiller adopts international famous brand: German BITZER screw compressor is the central part of the refrigeration host, combined with PLC automatic control system, according to the inlet and outlet water temperature or summer and winter operation mode automatically select a section of cooling or multi-stage cooling, with the characteristics of energy saving, time-saving, stable and environmental protection, than the traditional concrete cooling system (chiller + ice unit) energy saving 10-35%, while greatly reducing the cost of investment.

3. Concrete cooling chiller can provide: 1 ton / hour ~ 150 tons / hour concrete special chilled water or ice water mixture, according to the type of mobile chiller station design, production, the whole machine for container mode factory, to the industrial site only need the user to equip the power supply, connect the pipeline can be used. In order to meet the actual production needs of our customers as much as possible, we can design, produce and support units according to the customer's on-site construction requirements.

4. Specifications of concrete cooling chiller unit: 5 tons / hour ~ 200 tons / hour concrete special chilled water or ice water mixture, according to the type of mobile chiller station design, production, the whole machine for container mode factory, to the industrial site only need the user to equip the power supply, the pipeline can be used. In order to meet the needs of customers as much as possible to buy the same demand as production, cheap equipment, we can design, production, construction and excellent after-sales service according to your requirements.

5. For special reasons such as building construction, refrigeration equipment engineering installation, need to build a refrigeration room, short project period, heavy tasks and other characteristics, our company combined with many years of experience in refrigeration and engineering technology installation, self-developed, designed, manufactured a series of mobile refrigeration units. According to the type of mobile chiller station design, production, the whole machine for container mode factory, to the industrial land only need the user to equip the power supply, connect the cooling water source, and the freezer and the equipment between the pipeline connection can be used, no special machine room, at the same time can be designed according to the needs of different engineering installation of different configurations and different dimensions of the integrated unit. The main engine refrigeration range of the integrated unit is wide, and the temperature range of the chilled aqueous solution is wide.

★ Humanized concept: built-in German Siemens PLC programmable control system, LCD touch screen operation interface is simple, let you the operation of the equipment become a show of hands. Fault intelligent display system, so that the fault problem is simple to troubleshoot.

-

Concrete cooling chiller characteristics:

First, the heart of the most efficient semi-hermetic compressor unit - imported high-quality screw compressor, its 5:6 ultra-efficient screw rotor compressor, 20-30% higher energy efficiency than the general compressor, reliable efficiency, easy maintenance, accurate capacity control, wide range of applications.

1. The latest asymmetric rotor tooth shape.

2. Four-stage or segmentless capacity control system.

3. Built-in differential pressure oil supply lubrication system.

4. Low vibration and low noise.

Second, the microcomputer accurately controls the temperature of the unit microcomputer controller adopts a large screen dot matrix liquid crystal display, with a good full-Chinese man-machine dialogue interface to achieve full-function automatic control. The LCD screen instantly displays the working condition of the machine, the precise monitoring group runs in the best state, its light-touch panel is well sealed, waterproof, dustproof, anti-corrosion, and the button life is long. Graded and stepless energy control is used in general air conditioning systems, equipped with 100%, 75%, 50%, 25% graded energy control systems. This ensures maximum energy savings at partial load in the unit. However, if you need to precisely control the water temperature, all models can be equipped with stepless energy control according to user requirements.

Third, the heat exchanger with high operating efficiency adopts high-efficiency bellows, plus high-efficiency screw compressor, which ensures the high-efficiency operation of the unit. The most reliable protection and auxiliary components. The chiller has the following components to prevent any operation failure: compressor protection timer, overcurrent relay, compressor motor temperature sensor, anti-freeze thermostat, sight mirror, oil heater, compressor reverse phase protection relay, high and low pressure protection, exhaust high temperature protection, safety valve, soluble plug.

Concrete special chillers are widely used in national bridges. Railway Bureau, Highway Bureau, Construction Bureau, Water Conservancy and Hydropower Bureau and other large-scale concrete projects are used, such as: high-speed rail, tunnels, hydropower, dams, hydropower stations and other civil concrete mixing and cooling. This unit has been well received by the majority of users since its launch. Welcome customers to inquire!

Packaging and shipping

Analyze products

formulate a scheme

Plan rectification

Safety debugging

Equipment manufacturing

Customer determines the plan

Understand customer needs

previous page

No.

next page

Online message

Related products